Mold and Core Painting System

This type of system is used in foundries to apply paint on molds or cores ,It is a system that can work with electricity or only air.

Advantages

–Elimination of pump and motor valve blockages caused by drying of paint

–Obtaining homogeneous paint by mixing the paint continuously

–Putting an end to paint losses in painting with brush and gun

–Stability

–Minimizing operator errors

-Uniform paint thickness over the entire mold surface, including deep pockets and vertical surfaces

–Reduction in mold erosion and therefore sand and refractory inclusions on the surfaces after casting

–Elimination of brush and surface correction marks

–Shortening the dyeing time and increasing the number of pieces coming out

–Improvement of detail images such as letter numbers

Places where painting is used

–For the styrofoam casting process

–For centrifugal casting

–To improve metallurgical properties

–To protect refractory and metal tools

Why do we paint

–To increase the quality of the casting and to eliminate surface defects.

–To avoid the following casting errors,

–Metal penetration

–Mold erosion

–Preventing Carbon/Phosphorus/Sulfur accumulation

-Gas errors

–Mold/Metal reactions

–Sand expansion faults

-Metallurgical faults

–Separation of casting from mold or core

Paint raw materials used

Graphite, Zircon, Silica, Alumina, Magnesite, Mullite, Chromite, Quartz, Olivine, Plorophyllite, Talc, Mica

Painting Process;

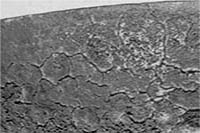

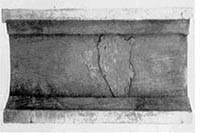

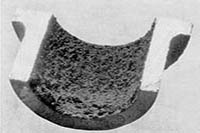

Smooth part surface obtained as a result of paint application;

Surface problems that may arise without paint application;