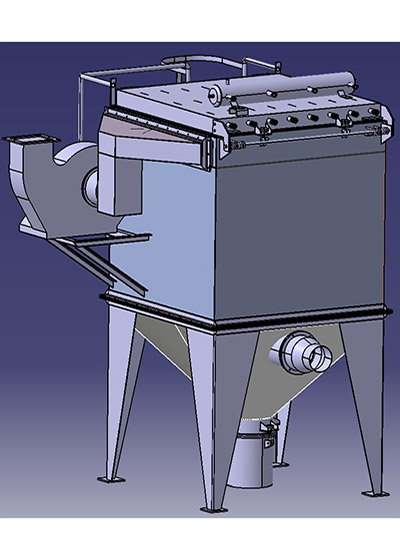

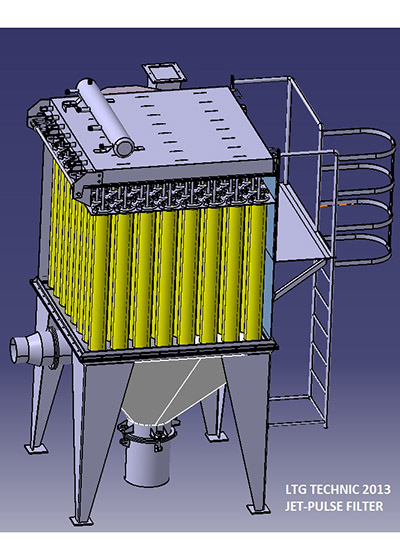

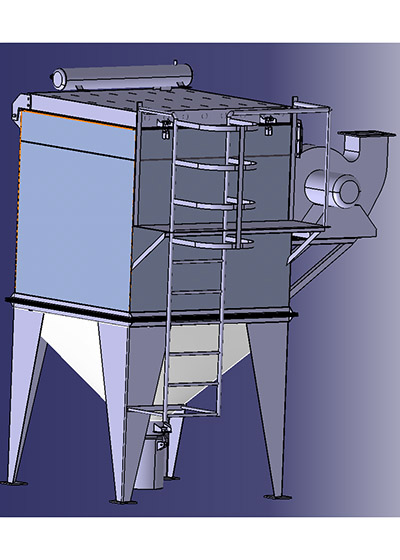

Jet Pulse Filters

This type of filters performs filtration in a completely dry environment with filter elements (Needle Felt) obtained from artificial fibers of different types (selected according to the physical and chemical properties of the dust to be filtered). Dust accumulated on the outer surface of the filter bags during filtration is automatically cleaned using compressed air (Jet-Pulse Technique).

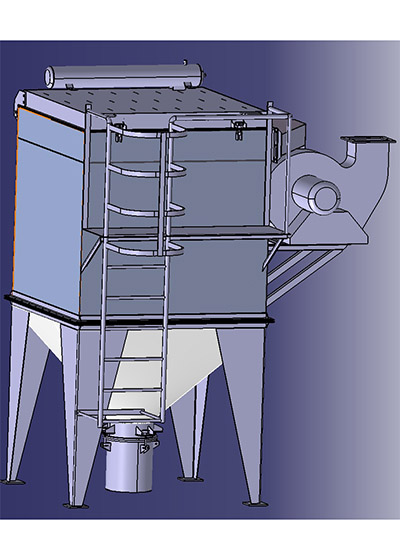

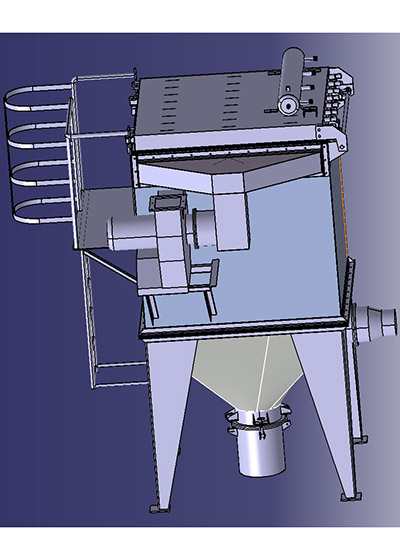

There are models with suction fan and foot type.

WORKING PRINCIPLE

With the effect of the vacuum created by the ventilator at the end of the system (after the filter), dusty gases pass through the pipes and enter the bunker from the upper part of the bunker via the inlet hood and disperse into the bunker before reaching the bags. It is done from the outside of the filtering bags to the inside. At the same time, the dust layer accumulated on the bag surface also helps filtering. The cleaned gases pass through the inner surface of the bag and fill the clean gas cell at the top, and pass through the clean gas outlet pipe and are thrown into the atmosphere from the fan chimney. It is taken out from the filter bottom bunker with Air-Lock and Screw Conveyor or collected in a bucket.During the cleaning process, the compressed air effect is provided to the filter bags with short pulses.These air pulses provide two types of effects on the bag: The vibration created by the compressed air on the bag. and accordingly, the dust on the surface of the bag is spilled. The compressed air dispersed on the inner surface of the bag inflates the bag, and the air trying to escape from the inner surface to the outer surface opens the bag pores and throws the dust out, The process of spraying the compressed air into the filter bags in short time intervals It is provided by the Chtronic Timer. Timer cleaning intervals and times can be adjusted. Flattening of the bags by the effect of vacuum (negative air pressure) inside the filter body is prevented by a cage. The assembly or replacement of the bags is done from the top, that is, from the clean side, after the filter top cover is opened.

JET-PULSE BAG FILTER TYPES

In general, Jet-Pulse Bag Filters are divided into two main types, but they are also divided into groups among themselves:

FILTERS FOR DEDUSTING PURPOSES

MODULAR TYPE PACKAGE FILTERS

They are manufactured in rectangular or square cross-section body structure. Flow ranges vary between 500 m3/h and 6,000 m3/h. They are used in small dust processes to be vacuumed from one or two points. Some of the usage areas are:

Food and Plastic Industry,

Precious Metal Processing Sector,

Chemical Industry

MODULAR TYPE HIGH CAPACITY FILTERS

They are manufactured in rectangular or square cross-section body structure. Flow ranges vary between 6,000 m3/h and 100,000 m3/h. They are used in dedusting processes at multiple points. The dust, which is vacuumed with a hood from each of these points, is collected in a central collector pipe and filtered? is passed through

Usage areas:

Cement Industry,

Iron and Steel Industry

Chemical Industry

Mining Industry

link=”url:https%3A%2F%2Fwww.youtube.com%2Fwatch%3Fv%3Da5fU7Y5jjiE|||”]